Medical Tube Extrusion 101 : A Guide to Essential Machinery and Processes

- Understanding Medical Tube Extrusion

- Key Machinery in Medical Tube Extrusion

- Techniques for Medical Tube Extrusion

- Material Selection in Medical Tube Extrusion

- Automation and Control in Modern Extrusion Lines

- Quality Assurance in Medical Tube Extrusion

- Advancing Innovation in Medical Tube Extrusion

- Partner with Medical Tube Extrusion Expert - TwinScrew

- Achieve Excellence with TwinScrew

Medical tube extrusion is a cornerstone of healthcare manufacturing, providing critical components for devices like catheters, IV lines, and surgical tools. This guide simplifies the technical complexities of medical tube extrusion, focusing on the essential machinery and processes involved in creating these indispensable products.

1. Understanding Medical Tube Extrusion

Medical tube extrusion is a continuous process that shapes raw materials into precise, functional tubing. The resulting tubes must meet stringent quality standards to ensure patient safety and device reliability. By mastering the fundamentals, manufacturers can optimize production to achieve consistency and high performance.

2. Key Machinery in Medical Tube Extrusion

Extruder

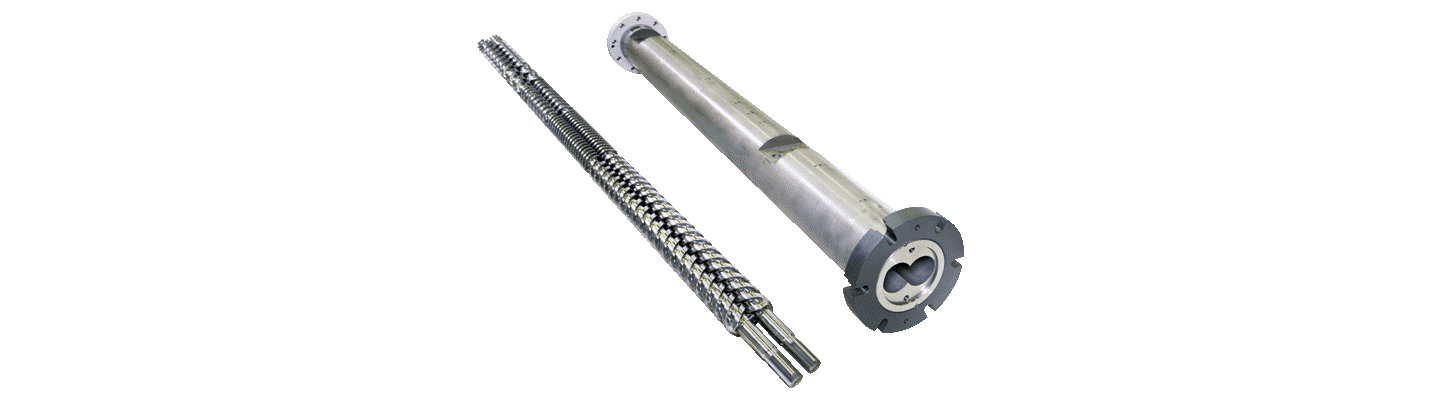

The extruder serves as the heart of the extrusion line, transforming raw materials into molten plastic for shaping. Advanced extruders feature:

- Precision Screws and Barrels : These components are meticulously engineered to ensure consistent melt quality and uniform material flow, which is crucial for maintaining the high precision required in medical tubing production. Specialized screw designs also allow for optimized mixing and minimal material degradation.

- Temperature Control Systems : Modern extruders are equipped with multi-zone heating systems and advanced sensors that prevent material degradation by maintaining uniform viscosity across the barrel. This level of control ensures the final product meets stringent quality standards, even during long production runs.

Dies and Calibration Systems

Dies determine the tubing’s shape and dimensions, while calibration systems ensure consistent sizing and roundness. These components are critical to achieving the precise specifications required for medical applications. Specialized dies include:

- Multi-Lumen Dies:These advanced dies enable the creation of tubing with multiple internal channels, essential for applications requiring simultaneous fluid or gas transfer, such as multi-channel catheters.

- Micro Dies:Designed for ultra-small tubing applications, these dies achieve unparalleled precision, producing smooth internal surfaces and ensuring the structural integrity needed for micro-medical devices.

Calibration systems enhance accuracy by maintaining consistent dimensions throughout the extrusion process. Automated calibration equipment further reduces variability and improves production efficiency.

Cooling and Cutting Units

Efficient cooling tanks stabilize the tubing post-extrusion, ensuring it retains its intended shape and dimensions. Advanced cooling systems use precise temperature regulation to prevent deformation and ensure uniform cooling across the tubing’s surface.

Cutting units, on the other hand, guarantee precise tube lengths by utilizing high-speed, automated mechanisms. These systems often incorporate programmable settings to meet various length requirements, ensuring versatility and reducing waste. Together, cooling and cutting components work seamlessly to maintain product integrity while boosting overall production efficiency.

3. Techniques for Medical Tube Extrusion

The choice of extrusion technique depends on the application’s requirements

-

Single-Layer Extrusion:

Produces uniform tubing for general use. -

Co-Extrusion:

Combines materials to create multi-layer tubing with enhanced properties, such as biocompatibility and durability.

4. Material Selection in Medical Tube Extrusion

Choosing the right material is crucial for meeting functional and regulatory standards. Common materials include:

-

PVC:

Flexible and cost-effective, ideal for general medical tubing. -

Silicone:

Biocompatible and suitable for implantable devices. -

Polyethylene (PE):

Excellent chemical resistance and flexibility.

5. Automation and Control in Modern Extrusion Lines

Automation plays a pivotal role in ensuring precision and efficiency throughout the medical tube extrusion process. Modern extrusion lines are equipped with advanced real-time monitoring systems that provide immediate feedback on operational parameters, allowing operators to identify and address potential issues promptly. Programmable logic controllers (PLCs) enhance this process by automating critical adjustments, ensuring consistency and reducing the margin for error. These systems not only optimize product quality but also improve overall productivity by minimizing downtime and waste. Moreover, the integration of smart manufacturing technologies enables seamless connectivity across production units, paving the way for data-driven decision-making and continuous improvement.

6. Quality Assurance in Medical Tube Extrusion

Maintaining high-quality standards is essential for medical applications. Quality control measures include:

-

Dimensional Verification:

Ensuring tubing meets precise tolerances. -

Material Testing:

Verifying compatibility and performance under sterilization conditions.

7. Advancing Innovation in Medical Tube Extrusion

The future of medical tube extrusion lies in innovation. Emerging technologies include:

-

Microextrusion:

For creating ultra-thin tubing used in minimally invasive surgeries. -

Industry 4.0 Integration:

Smart manufacturing systems enhance process traceability and efficiency.

8. Partner with Medical Tube Extrusion Expert - TwinScrew

Collaborating with industry-leading manufacturers ensures access to state-of-the-art machinery and tailored solutions. We offer customized plastic extrusion lines, advanced automation, and unparalleled technical support to help clients meet their manufacturing goals. TwinScrew’s deep expertise ensures precise, efficient, and reliable production, tailored to the unique requirements of medical tube manufacturing.

Achieve Excellence with TwinScrew

Medical tube extrusion demands a thorough understanding of machinery, materials, and techniques to produce high-quality products. By leveraging cutting-edge technology and adhering to stringent standards, manufacturers can ensure their products meet the needs of modern healthcare.

If you’re looking for reliable plastic extrusion machines, equipment, or complete medical tube extrusion lines for medical tube manufacturing, TwinScrew is your trusted partner. With our advanced solutions and industry expertise, we help you achieve your manufacturing goals with precision and efficiency. Contact us today to learn more about how we can support your extrusion needs.

Related Articles