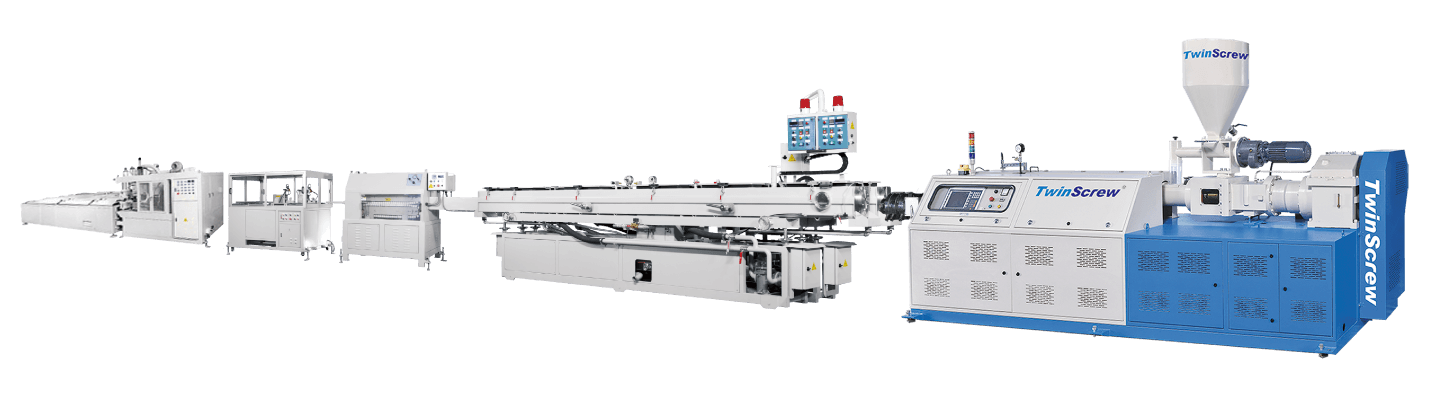

Twin Screw PVC Dual Line Rigid Pipe Making Machine

Description

The PVC pipe extruder is a machine that produces PVC pipes by melting and shaping PVC pellets or powder. The extruder consists of a barrel, a screw, a motor, a heating system, and a die. The PVC pellets or powder are fed into the barrel through a hopper, where they are melted and homogenized by the heat generated by the heating system and the rotation of the screw. The molten PVC is then forced through a die that shapes it into a tube of the desired size and thickness.

Related Video

-

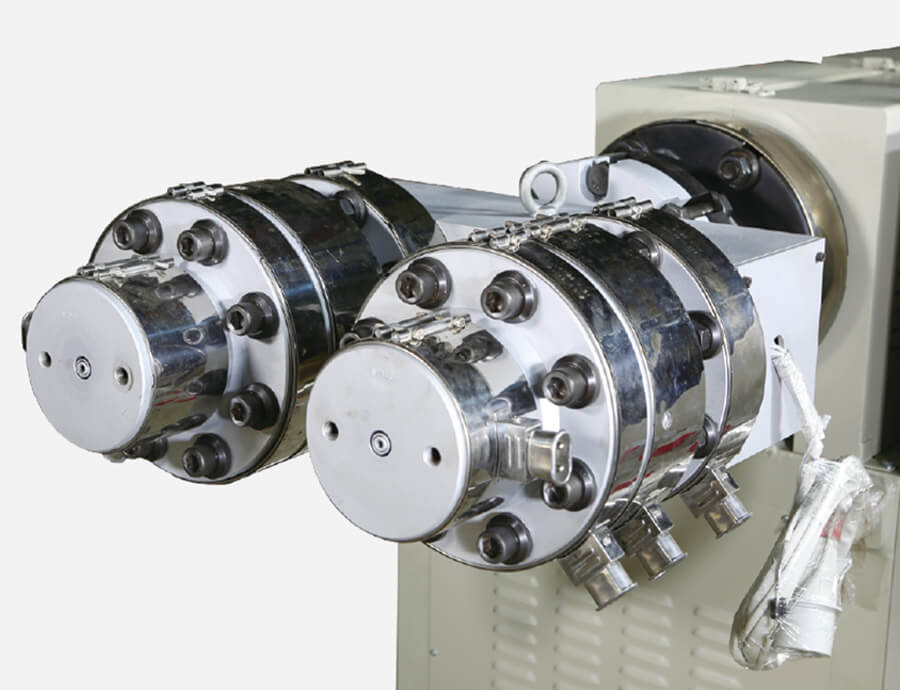

Dies for PVC Pipe Extrusion

-

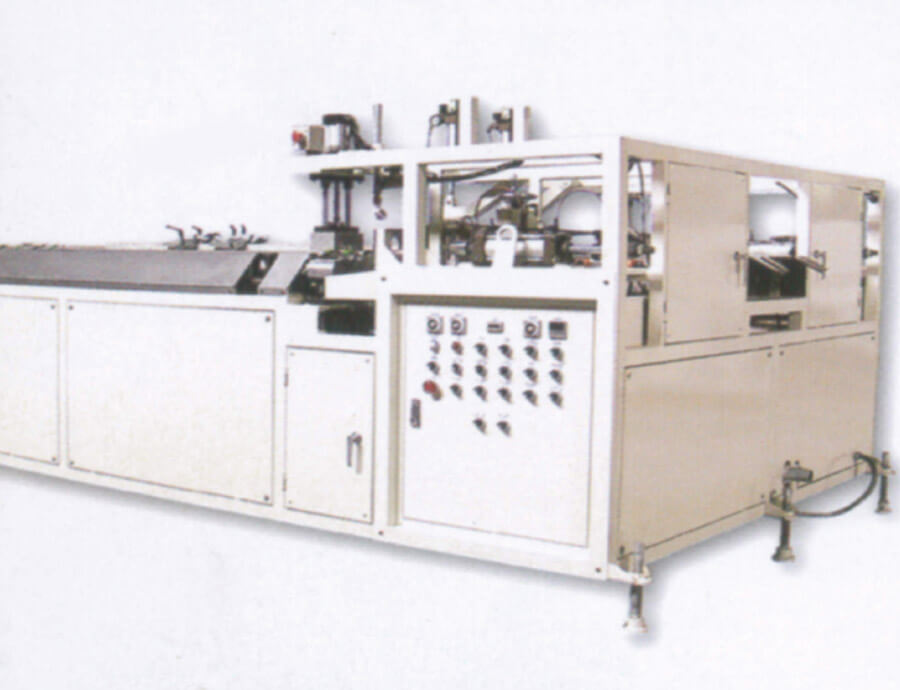

Automatic Belling Machine

-

Non-dust Cutting Machine

-

Haul-off Machine

-

Vacuum Spray Cooling Tank

-

Operation Control System

-

Twin Screw Extruder

The concept of the spider die guarantees outstanding product characteristic for PVC material.

The benefits:

Ideal residence time profile over the whole flow cross-section

Homogeneous melt distribution

Simple and reliable handling

on line production

Friendly operating

Low maintenance

Low dust pollution

Easy to recycle the waste

2.Improved torque-distribution unit with hardened, ground shafts and gear

3.Longer lasting processing unit service life (lower specific drive energy.)

4.Cost reduction.

5.Increased process reliability (modern control technology.)

6.Homogenous

7.User friendly

8.Touch screen.

9.Intelligent temperature control.

10.Easy service and maintenance.

11.Easy synchronization with other machinery.