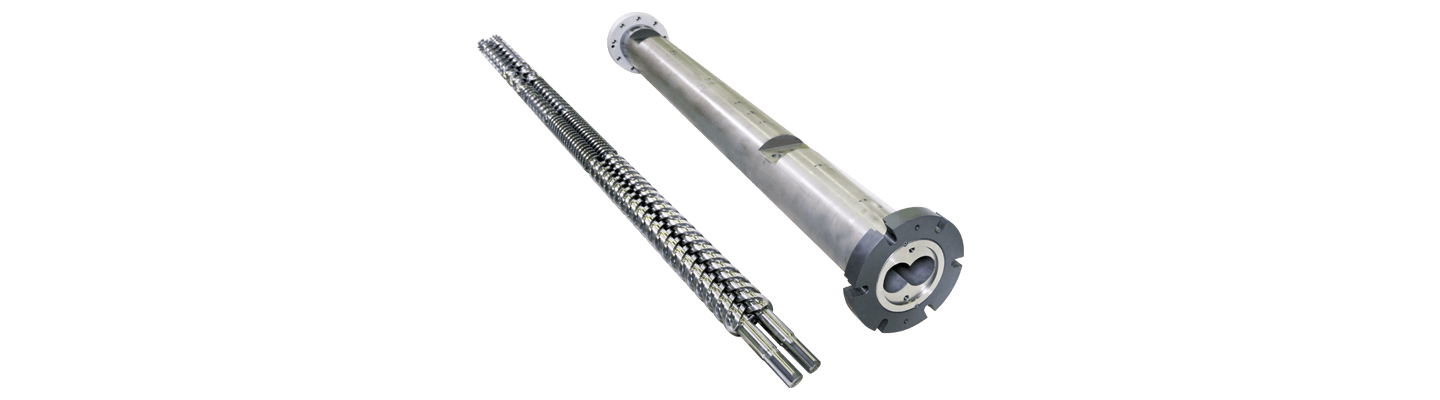

Extruder Screws and Barrels

Applications

Description

We develop and produce single screws and twin-screw, their diameter ranges up to 132 mm and length to 3,700 mm. We only use a material that is imported from Germany or Japan once the geometry has been determined. The screws are produced by the following individual processes.

- The blanks are prepared and annealed.

- Modern CNC lathers ensure a high degree of constant quality.

- Well-Proven special boring systems are used for producing the cooling channels.

- The screw geometry is milled out by computer numerical controlled machines.

- Before they undergo heat treatment, the workpieces are checked for warpage. Deviations are corrected immediately.

- The screw flights are polished by several stages, with surface roughness below Ra 0.8 gm.

- An acceptance report is written out of each screw during the final inspection.

One program comprises barrels of diameter up to 132 mm and length of up to 4,000 mm, we use a material that is imported from Germany or Japan. We supply barrels for single-screw or twin-screw that is produced by the following individual processes.

- Precise positioning of the barrel bores. The latest special boring machines are employed.

- Finishing the bore of the barrel by CNC lathe.

- Highest surface quality through honing of the barrel bores.

- Even the most difficult shapes can be machined to accept finishes on CNC machines.

- Highest wear resistance is obtained by deep Nitriding of the barred bores.

- Completed barrel is checked by gauging machine before delivery.

- An acceptance report is written out of each barrel during the final inspection.

Related Video

- For thirty-two years, TwinScrew has been designing and manufacturing fully computerized lines for pipe extrusion. PVC pipe extrusion line is one of our specialized items.

- The Parallel twin screw extruder has newly developed for its technologies in UPVC pipe extruded by increasing in the drive torques and innovative solutions to problems in politicizing, screw thermoregulation by self-regulating, sealed water cooling system, vacuum scavenging system and melt pressure control.

- One line equipment includes Main Extruder,Vacuum Spray Cooling Tank,Haul-off Machine,Automatic Traveling Saw, Automatic Belling Machine (or Down Table).

The concept of the spider die guarantees outstanding product characteristic for PVC material.

The benefits:

- Ideal residence time profile over the whole flow cross-section

- Homogeneous melt distribution

- Simple and reliable handling