Twin-Screw PVC Profile Extrusion Line

Description

PVC profile extrusion lines are production systems that are used for the extrusion of raw PVC materials into custom profiles of different shapes and sizes. These profiles find extensive use in applications such as window and door frames, pipes, electrical conduits, and decorative trim.

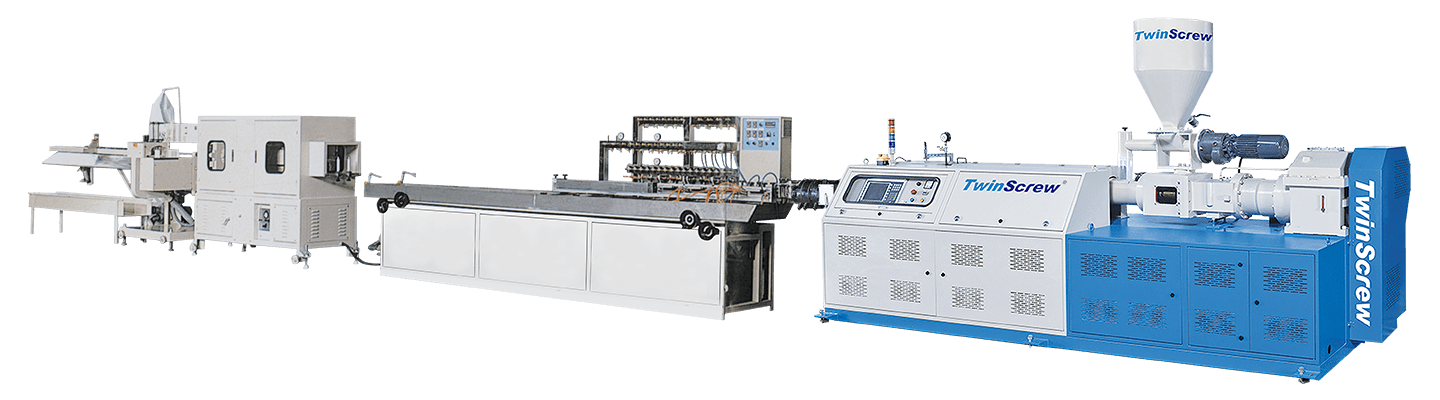

TW Series twin-screw PVC profile extrusion line can be used to produce window profiles, gutters, shutters, wall panels, decorative profiles, etc. It is one-line equipment including the main extruder, extrusion tool(die), cooling system, calibrating System, calibrating table, profile caterpillar haul-off, and saw/stacking(cutting) unit.

Our highly qualified team of engineers, operators, and technicians has always been searching for high technology, we can meet customers' various requirements.

Related Video

-

Benefits of Twin-screw over Single-screw Extruder

-

Features

-

Operation Control System

-

One-line Equipment

-

Advantages

Twin-screw PVC profile extruders offer several significant advantages over their single-screw counterparts, including:

-

Enhanced Mixing Capability

The primary advantages of a twin-screw PVC profile extruder is its superior mixing capability. The presence of two intermeshing screws creates a highly efficient and controlled mixing environment. This allows for better dispersion of additives, such as stabilizers, lubricants, and colorants, throughout the PVC melt. As a result, the final product exhibits improved homogeneity and consistent quality.

-

Improved Process Efficiency

Twin-screw extruders enable higher production rates and improved process efficiency compared to single-screw extruders. The twin-screw configuration provides better conveying and melting of PVC materials, ensuring a smoother and more stable extrusion process. This results in reduced material wastage, shorter production cycles, and increased overall productivity.

-

Enhanced Quality Control

The precise control and uniformity offered by twin-screw PVC profile extruders contribute to enhanced quality control. Manufacturers can achieve tight tolerances and consistent dimensions across their PVC profiles, ensuring compliance with industry standards and customer requirements. The advanced control systems of twin-screw extruders allow for real-time adjustments, minimizing variations and improving product consistency.

-

Greater Versatility and Flexibility

Twin-screw extruders offer greater versatility and flexibility in the PVC profile extrusion process. The ability to fine-tune various process parameters, such as screw speed, temperature, and shear rate, enables manufacturers to cater to a wide range of PVC formulations and product specifications. From rigid profiles to foam profiles, twin-screw extruders can handle diverse production requirements with ease.

-

Energy Efficiency and Cost Savings

Contrary to common assumptions, twin-screw PVC profile extruders can offer significant energy savings compared to single-screw extruders. The efficient mixing and melting capabilities of twin-screw extruders result in reduced processing temperatures and shorter residence times. This translates into lower energy consumption, reduced cooling requirements, and ultimately, cost savings for manufacturers.

-

Reduced Maintenance and Downtime

Twin-screw PVC profile extruders are designed for durability and ease of maintenance. The robust construction and advanced self-cleaning features of twin-screw extruders minimize material buildup and reduce the frequency of cleaning and maintenance operations. This results in less downtime and improved production efficiency.

- Reduction and torque-distribution unit with hardened, ground shafts and gear.

- Long service life for the processing units due to lower specific drive energy.

- Increased process reliability due to modern control technology

- High safety and Low maintenance frequency.

-

Extrusion Tool:

Extrusion die is designed segment type by stainless steel alloy and regulated through proper heating zones. Lifetime is long and easy to assemble. -

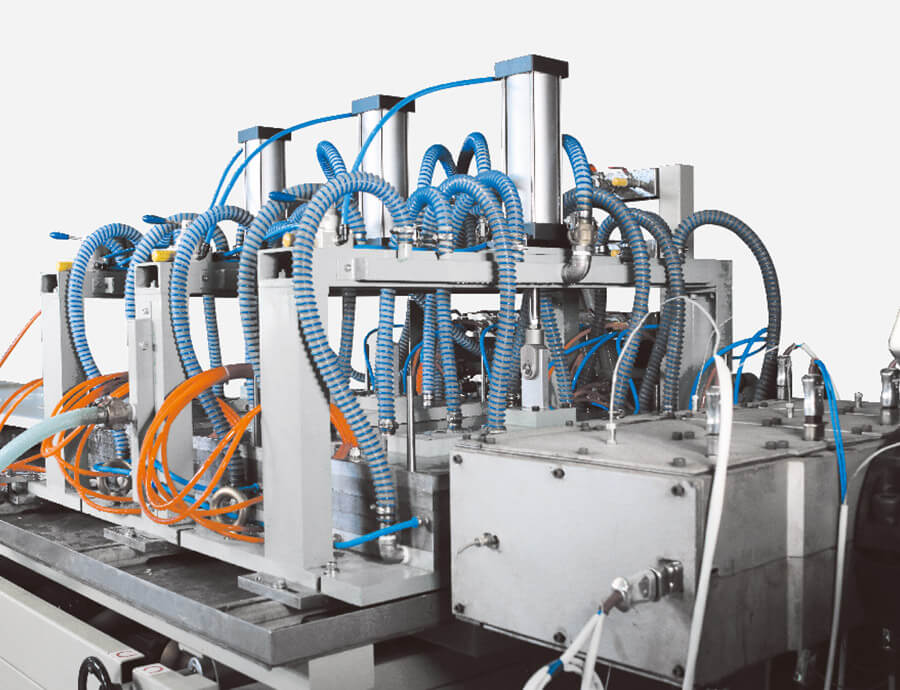

Calibration System:

Calibration is mounted on a common base plate.

Sectional calibrating methods with sufficient number of vacuum and cooling water connection. Its easy to assemble and pleasing to the eye.

Especially for calibrating of extruded hollow profiles and foamed profiles.

- Tradition operation-control type.

-

PC base machine operation:

Two parallel counter-rotating screws for better plasticizing and homogenization.

Improved torque-distribution unit with hardened, ground shafts and gear.

Longer lasting processing unit service life (lower specific drive energy).

Cost reduction.

Increased process reliability (modern control technology).

Homogenous.

User friendly.

Touch screen.

Intelligent temperature control.

Easy service and maintenance.

Easy synchronization with other machinery.

- Extruder: The extruder is the heart of the PVC profile extrusion line. It consists of a screw and barrel assembly, which melts the PVC resin and conveys it to the die. The extruder is responsible for achieving a consistent melt temperature, pressure, and homogeneity of the molten material.

- Die: The die is a specialized tool that imparts the desired shape and dimensions to the molten PVC. It determines the cross-sectional profile of the extruded material. Different dies can be used to produce profiles of various shapes, such as square, rectangular, round, or custom designs.

- Cooling System: After the molten PVC passes through the die, it enters the cooling system. This system uses a combination of air and water to rapidly cool the profile, solidifying it into the desired shape. Cooling is essential for maintaining dimensional accuracy and preventing warping or deformation.

- Calibration Table: The calibration table is a long, flat surface equipped with adjustable clamps or vacuum suction to hold and stabilize the profile during the cooling process. It ensures that the profile maintains its desired dimensions and shape as it solidifies.

- Haul-off Unit: The haul-off unit consists of one or more pairs of caterpillar-like belts or rollers that grip the cooled profile and pull it through the extrusion line at a controlled speed. The haul-off unit is responsible for maintaining tension and preventing stretching or distortion of the profile.

- Cutting Unit: The cutting unit is used to trim the extruded profiles into desired lengths. It can employ various cutting methods, such as sawing, guillotine cutting, or punching, depending on the specific requirements of the profiles being produced.

- Cost-effectiveness: PVC profile extrusion lines enable efficient and continuous production, resulting in lower production costs compared to traditional manufacturing methods.

- Design flexibility: These lines can produce a wide range of complex profiles with varying shapes, sizes, and surface finishes, allowing for customization and design versatility.

- High production output: PVC profile extrusion lines can achieve high production speeds and output rates, meeting the demands of large-scale manufacturing.

- Consistent quality: The extrusion process ensures consistent material properties and dimensions, leading to high-quality profiles with excellent surface finish and dimensional accuracy.