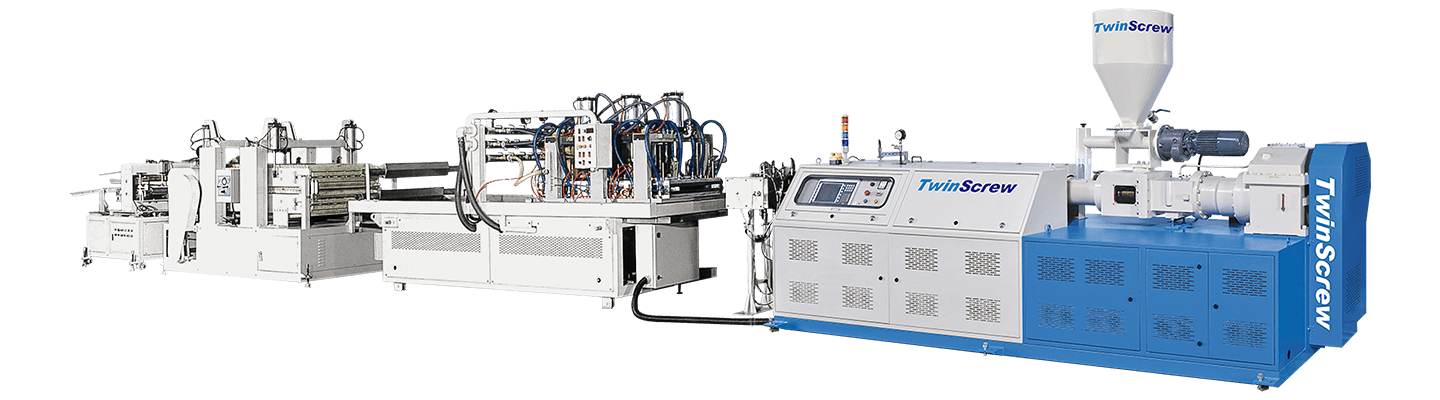

Complete Production Line For Large Volume Profile Extrusion Machine

Applications

Description

What is a large profile extrusion machine?

A large profile extrusion machine is a piece of equipment used to produce profiles by extruding a heated thermoplastic material through a die. The die is designed to create a specific shape or profile that matches the desired end product. A large profile extrusion machine is typically used for the manufacture of large profiles and can handle various thermoplastic materials such as PVC, PE, PS, and more.

This kind of equipment can be used to produce large-volume profiles, like PVC door panels, foamed PVC sheets, hollow roofing, corrugated sheet, etc. One-line equipment includes Main Extruder, Extrusion Tool, Calibrating System, Calibrating Table, Profile Caterpillar Haul-off, and Saws.

Large profile extrusion machines are an essential piece of equipment for the manufacturing industry, particularly for the production of large profiles such as plastic windows, PVC ceilings, cable trunks, decks, gutters, and more. These machines have several key features that make them ideal for producing high-quality profiles consistently, including high output capacity, precise control of the extrusion process, flexibility, and energy efficiency.

TwinScrew is a professional manufacturer of large profile extrusion machines

TwinScrew Industry spends much time and many engineers studying and developing this kind of Large volume profile extrusion. In addition, we continue to update the quality and functions of our equipment in order to let customers satisfied. Per our experience in this field, we trust we will try our best to meet customers' various requirements without problem.

Profile manufacturers can benefit greatly from using a large profile extrusion machine for their production needs, as it can help them produce high-quality profiles quickly and efficiently. With the ability to produce custom profiles by changing the die, large profile extrusion machines are a versatile and flexible solution for manufacturers in various industries.

There are several key features that make a profile extrusion machine ideal for producing large profiles, including:

- High Output Capacity: Profile extrusion machines can produce large quantities of profiles in a short amount of time, making them ideal for mass production.

- Precise Control of the Extrusion Process: Modern profile extrusion machines have advanced controls that allow for precise control of the extrusion process, resulting in consistent profile production.

- Flexibility: A profile extrusion machine can produce a variety of profiles by simply changing the die. This makes it a versatile piece of equipment for manufacturers that need to produce different profiles.

- Energy Efficiency: The large profile extrusion machines are designed to be energy efficient, helping manufacturers reduce their operating costs.

A large profile extrusion machine can be used for a wide range of applications, including:

- Windows: Large profile extrusion machines are commonly used to produce plastic windows. The machine can produce window profiles with different colors and sizes, making it easy to customize the end product.

- Ceilings: Large profile extrusion machines can be used to produce ceiling profiles for residential and commercial buildings. The machine can produce profiles with different textures and finishes to meet specific design requirements.

- Cable Trunks: Large profile extrusion machines can be used to produce cable trunking profiles that are used to protect and organize cables in buildings and infrastructure projects.

- Decks: Large profile extrusion machines can produce decking profiles for outdoor applications. The machine can produce profiles with different surface textures and colors.

- Gutters: Large profile extrusion machines can be used to produce gutter profiles for residential and commercial buildings. The machine can produce profiles with different sizes and shapes to meet specific installation requirements.

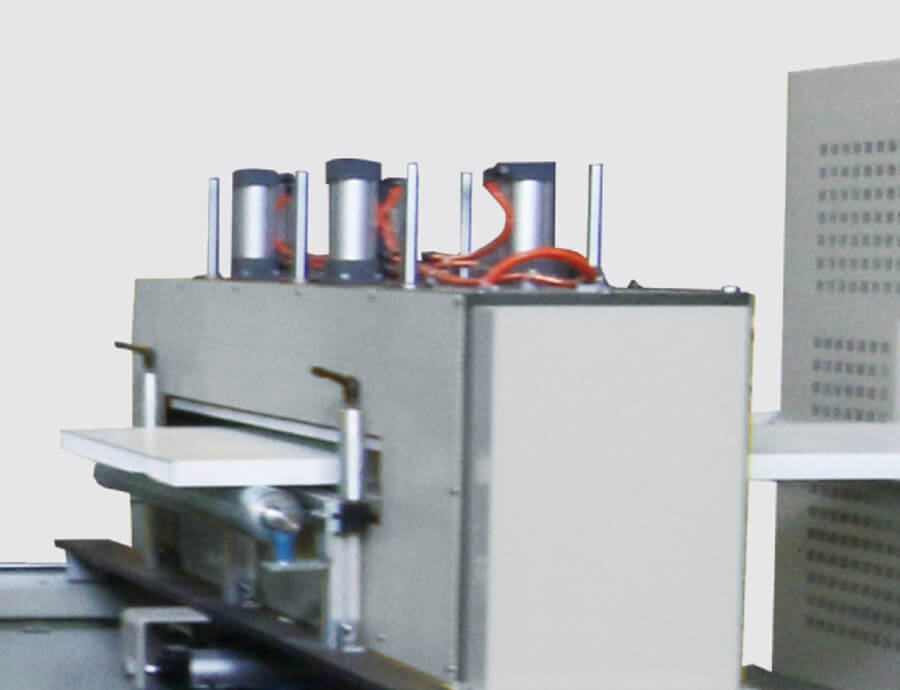

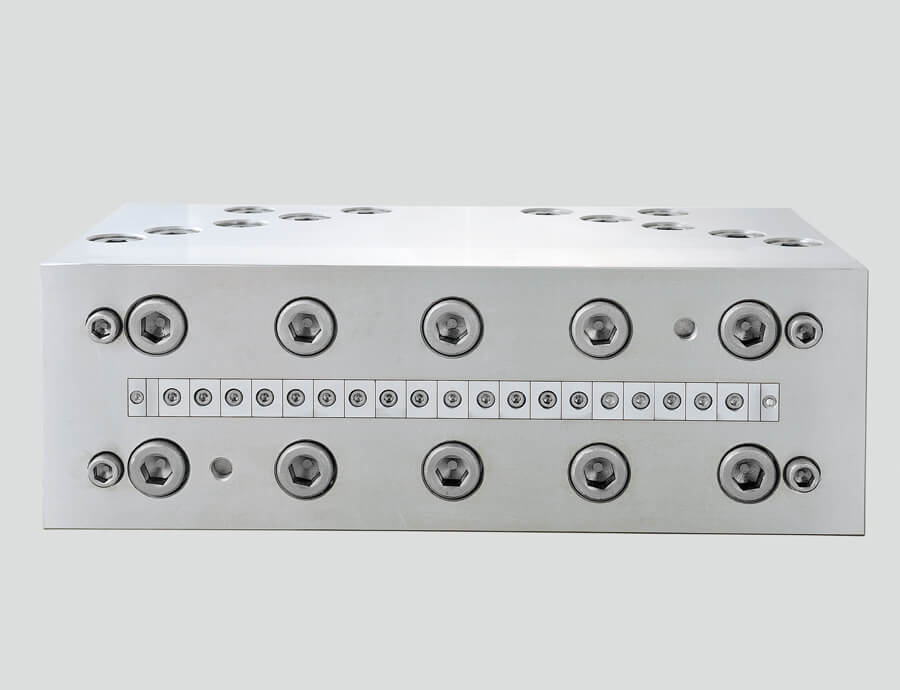

- Calibration is mounted on a common base plate.

- Sectional calibrating methods with sufficient number of vacuum and cooling water connection. It’s easy to assemble and pleasing to the eye

- Especially for calibrating of extruded hollow profiles and foamed profiles.

-

What materials can be used with a large profile extrusion machine?

Profile extrusion machines can handle various thermoplastic materials such as PVC, PE, PS, and more.

-

Can a large profile extrusion machine produce custom profiles?

Yes, a profile extrusion machine can produce custom profiles by changing the die.

-

What are some advantages of using a large profile extrusion machine?

Some advantages of using a profile extrusion machine include high output capacity, precise control of the extrusion process, flexibility, and energy efficiency.

-

What types of profiles can a large profile extrusion machine produce?

A profile extrusion machine can produce a wide range of profiles, including plastic windows, ceilings, cable trunks, decks, gutters, and more.

-

What are some factors to consider when selecting a large profile extrusion machine?

Some factors to consider when selecting a profile extrusion machine include production capacity, energy efficiency, precision control of the extrusion process, flexibility, and ease of maintenance.