Various PVC Profile Extrusion

In recent years, profile extrusion machines have become more popular in the manufacturing industry for their ability to produce various large profiles. These machines are commonly used to manufacture plastic windows, ceilings, cable trunks, decks, gutters, and more. It has become an essential piece of equipment for the manufacturing industry, particularly for the production of large profiles.

These extrusion machines have several key features that make them ideal for producing high-quality profiles consistently, including high output capacity, precise control of the extrusion process, flexibility, and energy efficiency.

Manufacturers can benefit greatly from using a profile extrusion machine for their production needs, as it can help them produce high-quality profiles quickly and efficiently. With the ability to produce custom profiles by changing the die, It is a versatile and flexible solution.

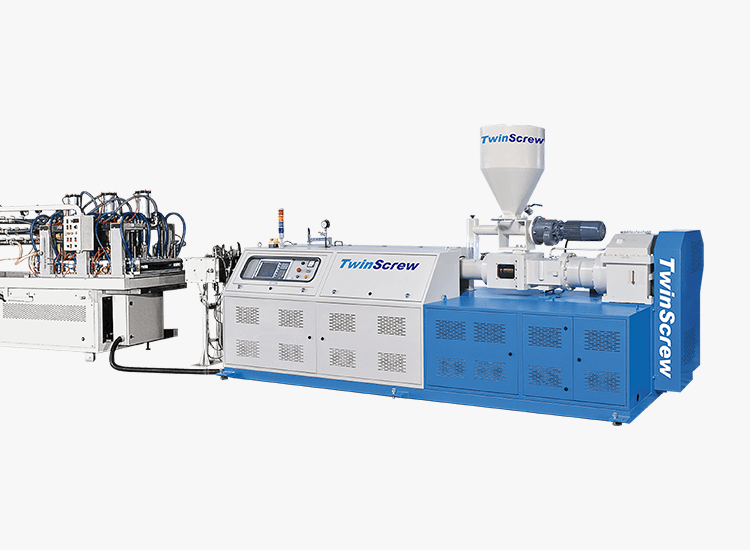

Twin-Screw control all technical procedures from R&D, design, manufacturing, finishing, to service. These fine products come from our home-made core unit and all the sophisticated equipment. We help our customers solving their essential problems by providing professional and flexible total solution more than just a twin-screw extruder.

Our professionalism has extended from PVC into profile extrusion and foaming area. It is able to produce varieties of construction materials including doors, windows, gutters, shutters, wall panels, decorative trims, and etc.

11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111

無效欄位無效欄位無效欄位無效欄位無效欄位無效欄位